All pilot stories of derring-do start off with “There I was…”

So, there I was in the Sting, just levelling off at 3000ft to the NW of Perth and the engine started running roughly. Check fuel pressure – fluctuating all over the place. OK, electric fuel pump on and it was still all over the place. Turn back towards the airfield and adjust to best glide speed, just in case it conks out completely. Luckily the Sting glides well so we were well placed to reach any of the runways.

The engine had picked up again but with occasional lapses of rough running. I needed to get on the ground. Unfortunately the airfield circuit (pattern for those in the US) was full of aircraft and a pleasure flying helicopter was just about to lift. Only one way to get priority…speak on the radio.

Now there is nothing more uncool than sounding like a panicky schoolgirl on the radio. It’s better to sound all Chuck Yaeger and nonchalant, so after a few seconds to calm down I transmitted:

“Mayday Mayday Mayday, Perth radio, Golf Sierra Mike with a rough running engine, inbound to the overhead from the Stanley area at 3000ft to position for a forced landing pattern”

It was awesome, Pete in the tower told everybody to clear the circuit, asked the pleasure flying helicopter to hold on the ground and called out the fire truck. I had the whole airfield to myself…

John who was just departing in the works helicopter gave me a wind check of 210/5 and then asked if I wanted them to hang around until I was on the ground. In best Chuck Yaeger style I said no thanks…maybe I should have been less Chuck Yaeger and more switched on. 210/5 is straight down the longest runway at Perth, but I elected to go for the runway I had taken off from. What a numpty – it is shorter and had a crosswind (only 5kt though).

I’ve already said many times that the Sting glides well. An engine failure halfway to France at 6000ft should end up in reaching the shore. Anyway the glide capability plus the fact that the engine wasn’t totally dead and was thus providing some thrust meant that I was high and fast on the final approach. A fairly vigorous S turning sideslip got the height off, but we were still fast. There’s nothing more infuriating than reaching the runway and not being able to get down because of excess speed, but eventually we touched down and only needed gentle braking in the remaining runway length available, so it can’t have been too bad.

The engine was still running quite smoothly so I asked Pete if it was OK to taxi back to the hangar. He readily agreed (he wanted his airfield back) and we proceeded off the runway and down the taxiway with our fire engine in tow like a faithful dog.

Over the next few days we got stuck into fault diagnosis. All fuel hoses were inspected for integrity and secure fitting. The fuel tank sender was removed, giving access to the top of the fuel tank for inspection – it was clear with no rags or bogies blocking the filters. I ran the electric fuel pump with the output hose going into a 3 litre jar – it took 45 seconds to transfer a litre of fuel. This equates to 80 litres an hour, and as the engine at full chat only burns 20lt/hr this was more than adequate.

I remembered a detail about the day of the mayday – normally with the fuel on and the electric pump on there is a second or two of dry running as it sucks air. This rapidly quietens down as the fuel reaches the pump and fills the galleries (cool word alert!). However on mayday day the dry running lasted a lot longer, almost as if it was sucking air. Now I know the tank pickup was under about 50 litres of Tesco’s finest unleaded, known in aviation circles as “MOGAS”, so the air must have been getting in somewhere else. And it was. The inlet hose to the gascolator (another cool aviation word) was not totally snug against the fitting, and the hose clamp was slightly loose. Tightening this up (and all the other work) has cured the problem.

Now after investigating a problem like this and finding the fault, we don’t just blast off across the North Sea – it takes a structured approach to regain confidence in the aircraft.

First was a rather lengthy ground run of the engine at high RPM, including taxiing out to the runway to do a full power accelerate/stop. The aircraft passed these with flying colours and no recurrence of the problem.

It was at this point that there was a little interlude for our June trip to Sweden, more about that later. But obviously we didn’t fly the Sting…

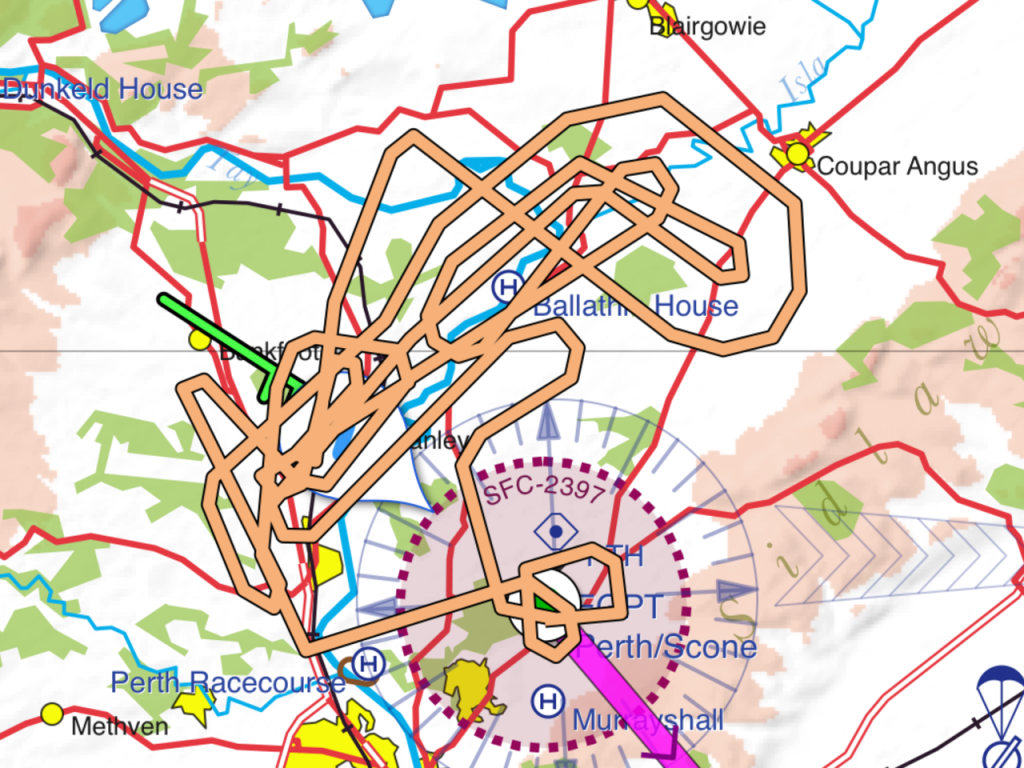

On return it was time for the air tests. I planned one to take off and not touch the throttle until we were at about 4000ft (it was during the throttle reduction that the fault originally occurred). Then I was going to fly around, always within gliding distance of the runway. And that’s what happened…it was kinda boring, chugging back and forth across the sky for an hour and a half at different power settings, but in that time the engine never missed a beat. The Skydemon software captured a trace of the flight:

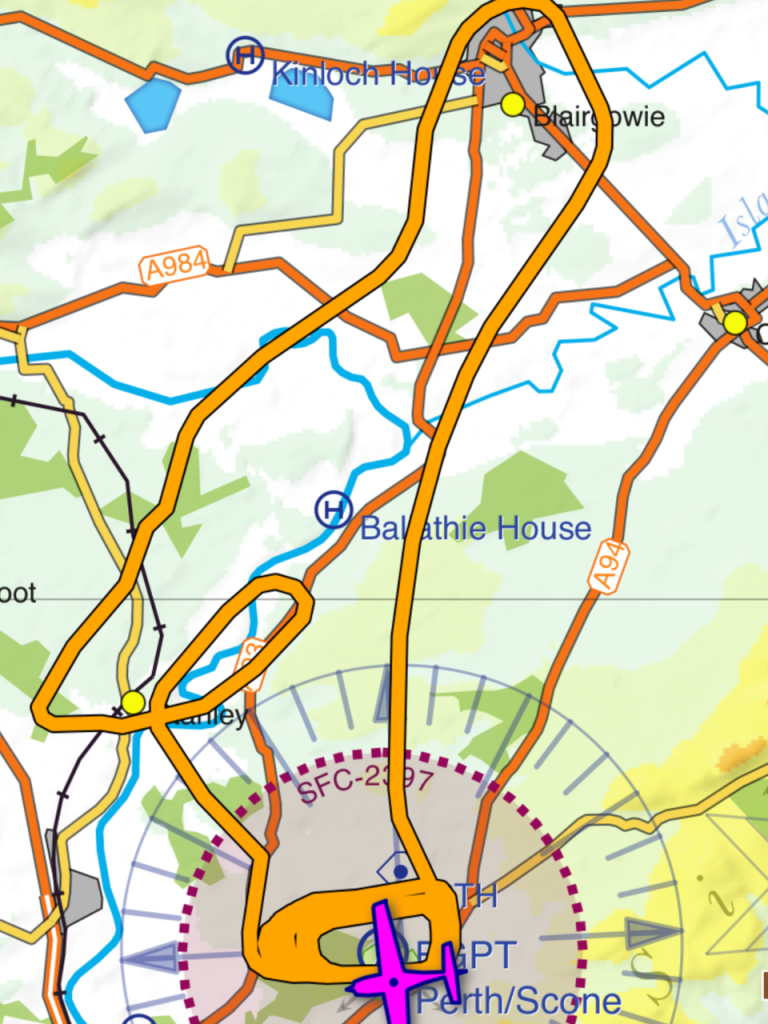

Next day was more adventurous – circuits of the airfield with a little excursion out to the north, well beyond glide back range. Lots of power changes from full power to idle and back again in quick succession, and once again the engine performed beautifully. Here’s the Skydemon trace:

The aircraft is fixed, and confidence has returned. As the aviation pioneers from 100 years ago might have said: “By Jove, I think we’ve cracked it old chap. Onwards to Sweden!”