I got a free pen! It has a stylus end for iPaddery and a little torch that comes on when you put the cap on the other end. It was handed out on Day One of the Rotax 912 Famil / Line Maintenance course run by the UK dealers CFS Aero. I thought I’d better do the factory course so that I can have a better chance of knowing what I’m doing when tinkering with the engine in the Sting. As it turns out I now have an authorisation number and am an iRMT – independent Rotax maintenance technician. So I can even do maintenance for others, if they want. I didn’t do it for that reason, I’m just happy to know a lot more that I did before and have the confidence to maintain my engine. But most importantly – free pen!

The course ran over two days in Coventry and cost £894, so they probably can afford to be a bit generous with their pens. Adding accommodation and travel brought the price up to over £1000, but the education as well worth it.

Day one was mostly theory in the classroom and also on the cutaway engines and components which they have in abundance.

Seeing the inner workings makes understanding what’s going on inside the thing a lot easier!

Day two was mostly practical. We changed oil, changed spark plugs, removed and inspected oil filters and much more including carburettor balancing on a running engine in the test bay…in fact everything required for a 100 hour service on the engine up to and including removal of the gearbox to send away for overhaul. Here Peter from Shropshire Light Aviation in the blue shirt is asking Hans from Franz Engines (Germany) about torque settings while Dirk from Styl Aviation (Antwerp) looks like he’s checking his phone.

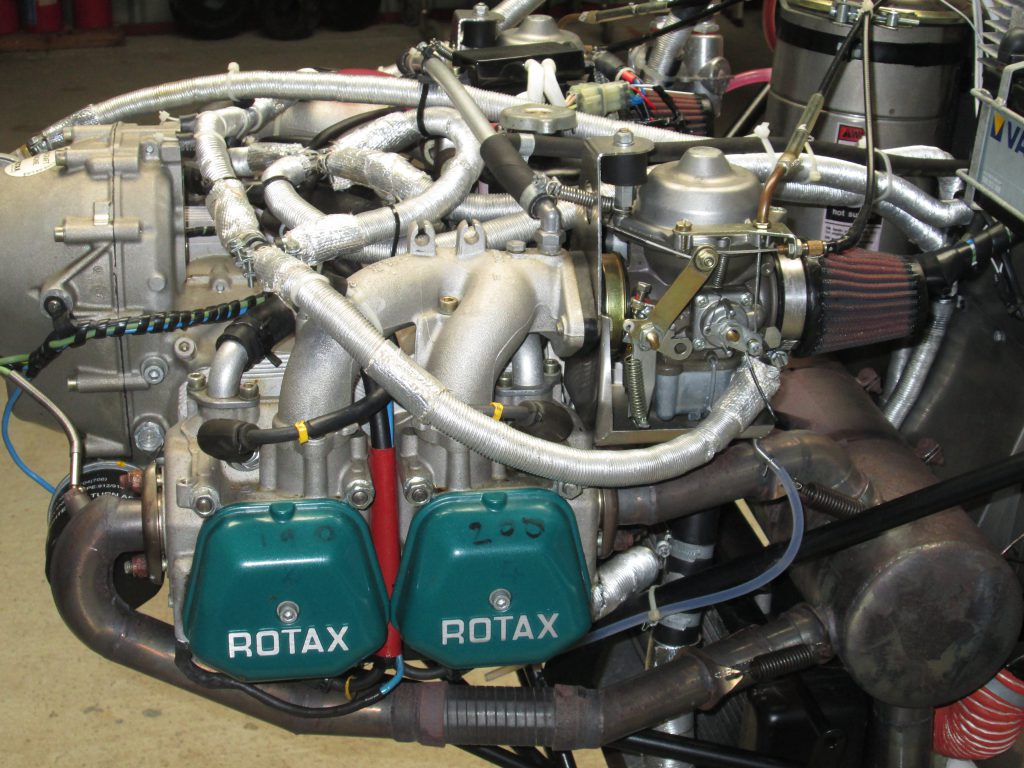

And this is what a Rotax 912 looks like with the gearbox removed:

It’s all very well looking at the training engines on their stands with all round access and half the systems removed, but now I have to put the knowledge to use and service this baby…

Wish me luck! But first, I have to buy loads of tools…